How to Connet the LED Sign Cables Correctly?

When the LED logo is connected to the circuit, you need to pay special attention to the key factor of some electrical safety, performance and long -term. The correct cable connection can ensure the safe operation of the Led Sign, extend the service life, and improve efficiency. The following are several points that should be paid attention to when connecting the LED cable:

1. Voltage and current matching

Voltage matching:

Before connecting the LED sign, make sure that the output voltage of the transformer power is matched with the rated voltage of the LED sign. For example, the common LED sign voltage is 12v. Using non -matching voltage may cause abnormal LED sign work or even damage it.

Power matching:

Make sure the maximum output power of the transformer can meet the requirements of the LED sign. If the power is insufficient, the LED sign cannot be used normally or even damaged.

2.Correctly connect positive and negative poles

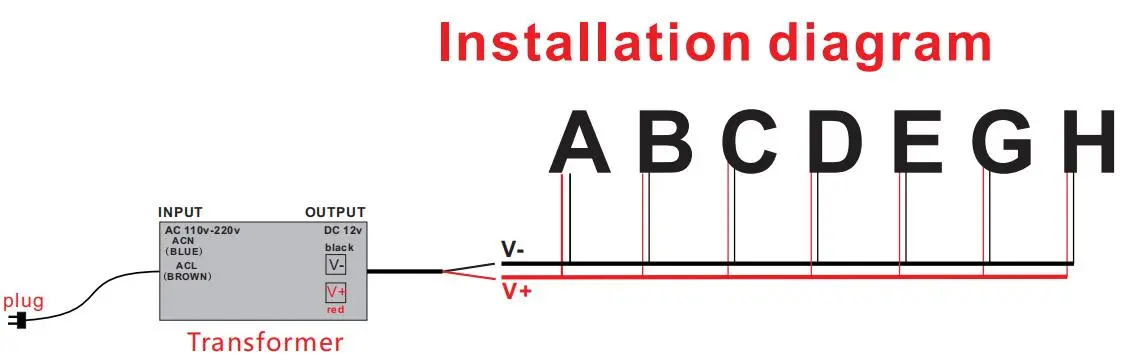

LED signs usually have clear polarity requirements, and positive (+) and negative (-) must be correctly connected. The wrong wiring can cause the LED sign to be unable to light up or even damage. When connecting the transformer supply, ensure that the positive line (usually red) of the cable connects the positive extreme of the transformer, and the negative line (usually black) connects the negative extreme of the transformer.

LED cables and transformer ports usually have polar signs (+and-). If it is not clear, please refer to the product manual or circuit diagram to ensure the correct connection.

3. Cable selection

Cable specifications:

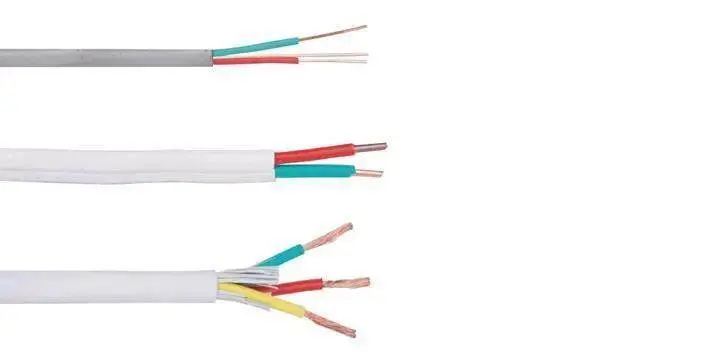

Select a cable with appropriate specifications to carry the required current. The cross -sectional area of the cable should be able to withstand the power consumption of the LED sign. Excessive cables may cause overheating or electricity loss. Common LED sign cables include 2 cores, 3 cores, etc.

Cable length:

Ensure that the cable length is appropriate. When using long cables, you can consider increasing the cross -section of the cable to reduce the loss caused by the resistance.

4.Wiring and fixing

Make sure the wiring terminal or plug should be tight to avoid loosening. The loose wiring may cause unstable or short circuit.

If you use the screw terminal, make sure the screw is tightened and avoid poor contact. If you use a plug -in wiring, make sure the plug is completely inserted.

Avoid poor contact:

At the place where the cable is connected, it can be protected with a insulation tape to prevent the exposed metal wires from contacting other objects, causing a short -circuit or electric shock risk.

Waterproof protection:

If the LED sign is installed in outdoor or humid environments, waterproof treatment is ensured at the cable and wiring. Waterproof joints, sealing, etc. can be used to avoid electrical failures from water invasion.

5. Switch and control

Switch position:

When installing the power switch, ensure that the switch position is convenient to operate, and avoid damage to the cable when frequent switches.

For systems that need to control multiple LED light, you can use segmented switches or light -adapter to facilitate adjustment.

6.Testing and inspection

Check before power -on:

Before power -on, check the contact between all connection points and cables to ensure that there are no naked wires or short circuit phenomena. Make sure that the transformer and cables are not overloaded, and all electrical connections are firm and not loose.

Test after power -on:

Turn on the power, test whether the LED logo is on normally, and check if there is any flashing, abnormal or not bright. If the problem is found, immediately check the circuit connection to find a part with wiring errors or damage.

7. Safety protection

Power off operation:

When connecting and adjusting the LED cable, it is necessary to ensure that the power supply has been disconnected to avoid electric shocks or short -circuit accidents.

Protection measures:

Use suitable tools and personal protection equipment (such as insulating gloves, goggles, etc.) to ensure the safety of the operation.